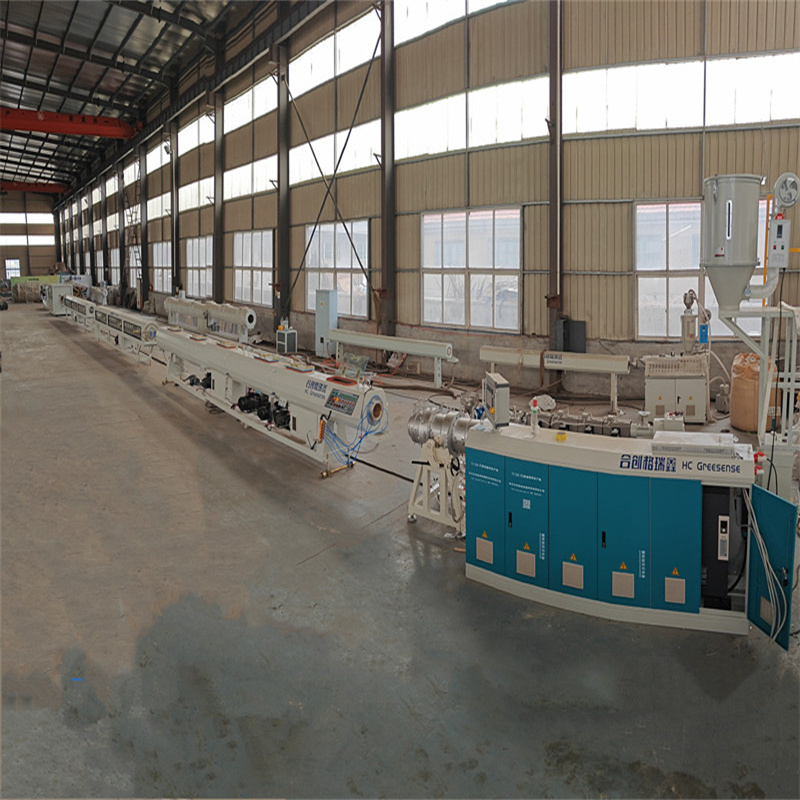

HDPE torumasin

QINGDAO COMRISE MACHINERY CO., LTD.

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

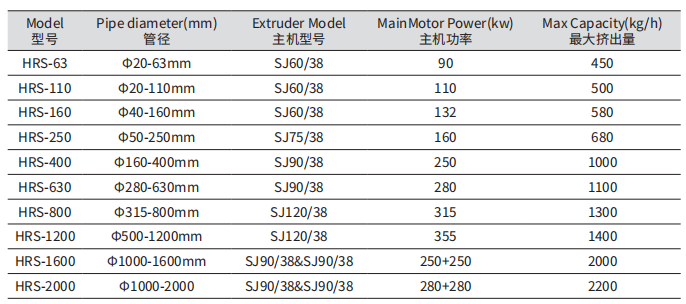

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

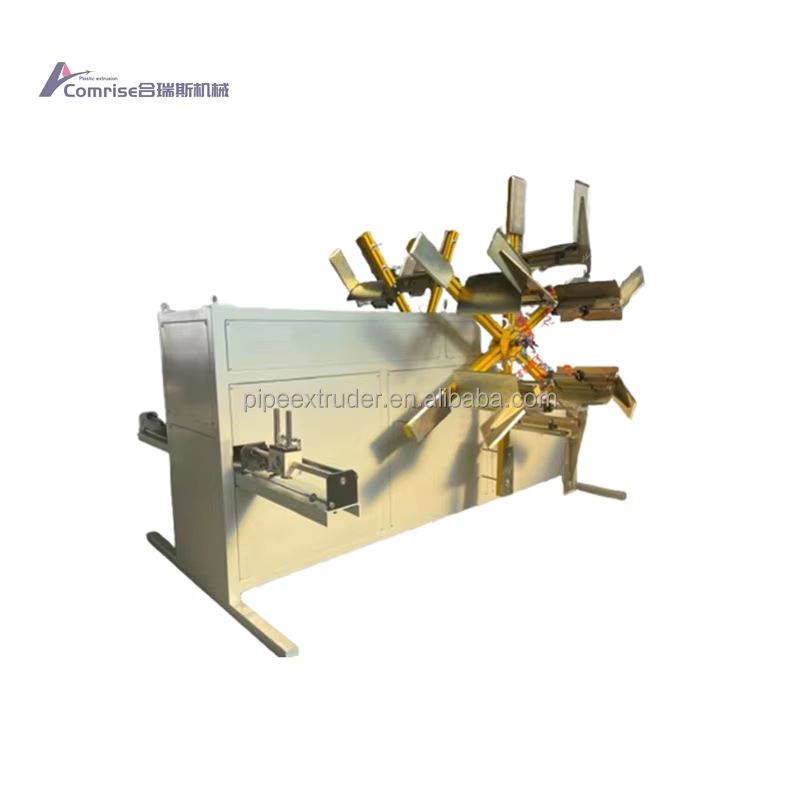

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

HDPE toru ekstrusiooni tootmisliin

Seltsi HDPE torude tootmismasin, Hiina Top tehase plasttorude tootmisliin, selle PE tootmisliiniga polüpropüleenitoru, saate ekstraheerida kvaliteetseid suure läbimõõduga vee- ja gaasivarude torustikke.20mm-110mm HDPE torude tootmisliin

Loe rohkemSaada päringHDPE toru väljapressimise tootmisliini masin

Seltsi HDPE toru ekstrusiooni tootmisliini masinaid kantakse peamiselt vee- ja gaasivarustustorudes. Oleme väga professionaalsed masina tarnija. See tootmisliin võib toota HDPE torus läbimõõduga 110 mm, 125 mm, 160 mm, 200 mm, 250 ja 315 mm, 110-315 mm HDPE torude ekstrusiooni tootmisliin, ja see võib sobida ka erinevate rõhuastete torude tootmiseks, mis ulatuvad SDR9-SDR-ist.

Loe rohkemSaada päringABA Kolm kihi CO ekstrusioon HDPE torumasin

Comrise Machine China Factory ABA Kolme kihi Co Extration HDPE torumasin on mõeldud peamiselt HDPE/PP torude tootmiseks, mida torusid kasutatakse peamiselt niisutamisel, veevarustuses; Ekstruuder saab töödelda PP/HDPE graanuleid (nii neitsi kui ka ringlussevõetud, isegi kriidiga täidetud komposiidiga). Selle masina väljund võib ulatuda nagu 150-300 kg/h, see on enamiku klientide jaoks populaarne valik.

Loe rohkemSaada päringHDPE torumasina tootmisliin

CMrise Factory HDPE torumasina tootmisliin võtab kasutusele Euroopa kõige rohkem tehnoloogia. See on uus energiasaavutus - säästes tootmist LIN, mis sobib HDPE, PP ja muude polüolefiini torude kiireks ekstrusiooniks. Võrreldes korpuse tootmisliiniga ulatub energia- ja säästmisefekt 35%-le ja tooteaste suureneb rohkem kui 1 korda, seega ei säästa see mitte ainult saidi ja tööjõu kulude säästmist, vaid ka tõhususe parandamist. 110-135mm HDPE torumasin on kena välimus. kõrgem automaatne kraad, tootmine usaldusväärne ja stabiilne.comRise on Hiina tipptasemel tarnija

Loe rohkemSaada päringHDPE ABA CO ekstrusiooni tootmisliin

Comrise tehase HDPE HDPE ABA CO ekstrusiooni tootmisliini saab kasutada HDPE suure läbimõõduga gaasi- ja PE-veetorude, 110-315 mm ABA Co CO ekstrusiooni tootmisliinil, millel on suurepärane jäikus ja painduvus, soojustakistus, vananemiskindlus, kõrge mehaaniline tugevus, keskkonnapinge vastupidavus ja suitsetud triibivastane. Süsteemid ja suure läbimõõduga HDPE torud on hakanud mängima väga olulist rolli linnavee- ja gaasivarustussüsteemides.

Loe rohkemSaada päringHDPE torumasina rida

Seltsi tootmise HDPE Pipe Machine Line on spetsiaalne seade, mis on mõeldud polüetüleenist torude tootmiseks. Neid torusid kasutatakse laialdaselt erinevates rakendustes, sealhulgas veevarustus, gaasi jaotus, niisutamine ja drenaažisüsteemid. 20-50 mm HDPE torumasin koosneb mitmest põhikomponendist, mis töötavad koos, et tagada tõhusa ja kvaliteetse torude tootmine

Loe rohkemSaada päring